Combing is a process which is introduced into the spinning of finer and high quality yarns from cotton. The carded materials (sliver) contain certain amount of short fibres, neps, fine kitty and leaf particles. Short fibres are a hindrance to spinning of finer counts where the number of fibre in the cross section of the yarn is less. The short fibres cause thick and uneven places in the yarn length and the yarn looks hairy. Apart from this, very short fibres do not contribute anything to yarn strength. Short fibres below a certain pre-determined length can be easily separated out by using comber.

Objects of Comber:

To remove the short fibres below a pre-selected length so that the spinner enable to produce finer or better quality of yarn that cannot be possible in carding state.

· Elimination of remaining impurities.

· Elimination of large proportion (not all) of the neps in the fibre.

· Formation of sliver having maximum possible evenness.

· To straighten the fibres.

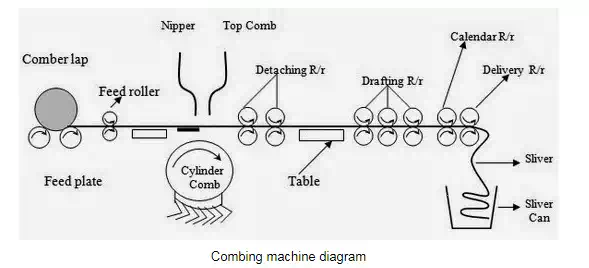

Basic Principle of a Comber (Combing sequence/Cycle):

One article has written about basic principle of a comber. So here only title of comber principle is given below.

· Lap feeding by feed roller

· Lap nipping by the nipper

· Combing by the cylinder

· Nipper opening and forwarding

· Detaching roller backward movement

· Piecing

· Combing by the top comb

· Detaching roller forward movement

· Starting a new cycle

· Cleaning of cylinder comb