Crazing

Often, when an amorphous brittle polymer is loaded in tension, a phenomenon known as crazing can occur. Crazing involves the formation of small crack-shaped regions that are drawn down but remain constrained by the surrounding material.

The drawn material ends up as ligaments that link the crazed surfaces. Eventually the crazes form cracks that lead to fracture. The crazes contain air giving them a white streaked appearance

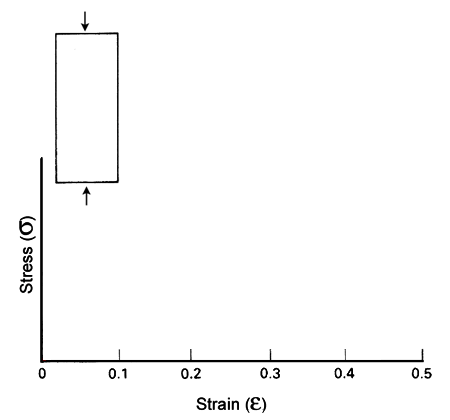

Shear Banding

Shear banding is produced in polymers when they are exposed to compressive stresses.

Small stress relieving cracks nucleate within the polymer parallel to the direction of maximum shear stress at an angle of 45°.

As the number of shear bands accumulates the overall strain of the material increases.

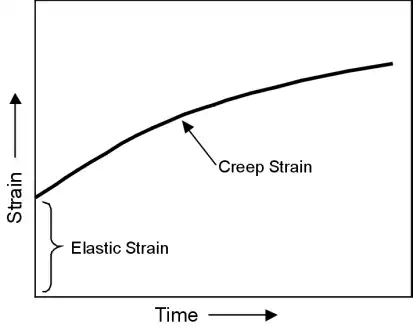

Creep

Of particular importance in the design process for polymers is an allowance for their susceptibility to creep deformation.

Under a constant applied load and at a constant temperature the deformation of the polymer will continue to increase over time.

The higher the applied stress or the higher the temperature the faster the deformation. Of particular concern with polymers is their relatively high creep rates at room temperature.

Below the Tg of a polymer creep is fairly limited due to the resistance to molecular motion from secondary bonds. However, aboveTg creep escalates sharply as polymers undergo a combination of elastic (recoverable) and plastic (permanent) creep deformation referred to as viscoelastic behaviour. In this temperature range the molecular chains are free to slide over one another in a manner known as viscous flow.