Fabrics are produced mostly from yarns. Few fabrics are directly produced from fibers. In Indian market 70% of the fabrics are produced by weaving. Among the other fabrics that is non woven fabrics lace making is worth mentioning along with needle punched and tufted fabrics. Felts are fabrics made directly from fibers without making yarns where fusible use is mostly emerging now a day.

The fabric construction process determines the appearance and texture the performance during use and care and cost of fabrics. The process often determines the name of the fabric for eg: felt lace, double knitt and jersey. The cost of fabrics in relation to the construction process depends upon the number of steps involved and the speed of process, the fewer the steps the faster the process, the cheaper is the fabric.

The fabric construction methods include weaving, knitting and non woven fabrics

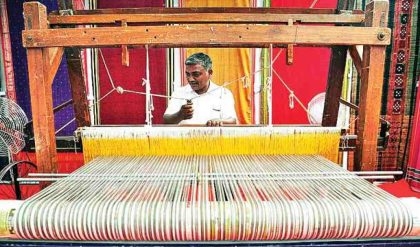

Weaving

Yarn is turned in to fabrics of garments by weaving, knitting, or felting. Fabrics are woven in long lengths from 40 to 100 or more yards and from about 20 to 60 inches in width. For a fabric to have strength and compactness combined with a fair degree of elasticity, the warp and filling threads must be interlaced.

This interlacing is called weaving and it is done on a loom. An interlacing where the filling threads are passed alternatively over and under the warp threads is called as a plain weave. It is the simplest of all weaves. If the fillings threads are passed one over and 2 under or more warp threads will result in twill fabrics. The surface of such fabric has pattern of parallel diagonal ridges.

If the warp threads or filling threads are considerably thicker then the ribweave is produced. Thus the very large number of variations of methods for interlacing the warp and filling threads makes to weave the wide variety of fabrics each of which has special properties and uses.

The beam of the warp threads is placed at the back of the loom and the threads are drawn from it across the loom from back to front to be wound on another roller. For the weaving of plain cloth, the threads are drawn through the eyes of two sets of heddles.

The filling threads pass over and under alternate warp threads which are lifted and lowered by the corresponding heddles. Toe cop with the filling threads is placed in a shuttle which is moved or thrown from side to side across the loom. Each pass of the shuttle lays one filling threads. The comb like reed described earlier beats the filling threads tight against the preceeding fill threads, as the fabric is woven it is slowly wound on to a roller in front of the loom.

Knitting

The knittings industry is a unique and distinct part of the textile industry. It is the second important method of making fabrics after weaving.

The knit characteristics are

• Bulky with surface effect.

• Loosely knitted or tightly knitted.

• Rib-purl-tricot.

Circular knit: Any fabric produced on a circular knitting machine. Double knit: A special type of rib knit fabric usually closed stitched with a pattern or design effect, generally thicker, heavier and more stable than jersey