Weaving of yarn into a fabric is performed on a weaving machine which has also been called a loom. Looms can be classified in two categories. Shuttle loom and Shuttleless

loom.

Shuttle Loom

These are mainly four types of shuttle looms.

· Hand loom,

· Non-automatic power looms,

· Automatic power loom,

· Circular loom.

In shuttle looms, winding of weft yarn on pirns and picking and checking of shuttle, which carries the pirns, are common feature, which limits the speed of the looms.

Disadvantages of shuttle loom are as follows. Smaller weft package, that require frequent replenishment. Limited scope for increase in speed and performance.

Noise and performance. Space and workers required for weft pirn winding.

Complicated mechanism on Multi-colour loom.

Shuttleless Loom

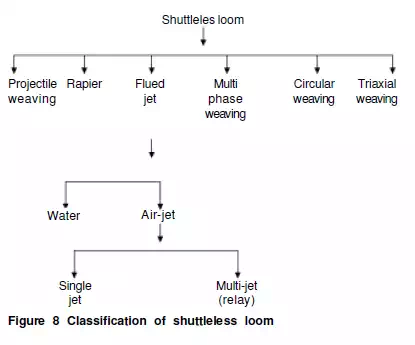

Shuttleless looms can be classified in six major groups. Four classification of the some in shown in Figure 8.

Projectile Weaving

This machine contains a bullet like shuttle, which is 90 mm long and weighs 40 g, technically termed as gripper projectile, which draws the weft thread into the warp shed from a large, stationary cross-wound package always from the same side5.

Features of Projectile Weaving Machine

· The gripper projectile are made from fine steel, 90 mm long, 14 mm wide and 6 mm thickness, weighs 40 g.

· The weft is drawn directly from a large, stationary cross wound package, where as weft winding is absent.

· During its flights through the shed, the projectile runs in a rake like steel guide, so that warp threads are touched neither by the projectile nor weft threads.

· Weft insertion rate ranges from 900 m/min to 1500 m/min.

· Sulzer projectile weaving machine available in twofour colour versions with working width of 190 cm to 390 cm.

· The upgraded version of machine is P7200 where as the model P7100 is with central microprocessor control.

· On P7200 model, weft insertion rate is 1500 mpm (3.92 m x 400 rpm)

Rapier Weaving

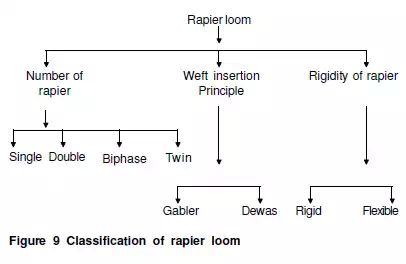

Rapier weaving machine produces versatile range of fabrics from outerwear fabrics to sophisticated label weaves6. Rapier looms are classified as shown in Figure 9.

Single Rapier

The weft is inserted during rapier insertion, and the weft put in the shed during rapier insertion.

Advantage

Problem of weft transfer does not arise and normal range of fabric can be woven.

Disadvantage

One movement of rapier is wasted. Loom speed is very slow. The maximum weft insertion rate

is 400 m/min.

Double Rapier

(i) These looms work on bilateral principle of rapier insertion. Two rapiers are used for insertion of a full pick in each shed. Both the rapiers enter simultaneously in the same shed from opposite

ends-one from the giver end with a weft thread and other from the taker end in empty condition.

(ii) The weft is transferred from the giver to the taker.

Weft Insertion Principle

Loop Transfer Gabler System

The weft is taken by the giver rapier from supply package in loop form.

Tip Transfer Dewas System

The end of weft is directly transferred from one side of the rapier to the other side at the time of proper shed opening.

Air-jet Weaving

Weft Insertion by means of airjet has made a major break through in the early 70s and its importance is increasing further being of its ability to weave a wide range of fabrics at a very high weft insertion rate of about 2000 m/min. The width restriction7 is about 150 cm for a single jet with confuser can be overcomed by a relay jet principle.

Different systems of air-jet weaving are as follows

(a) Single nozzle with confuser type guide.

(b) Multiple nozzle with guide.

(c) Multiple nozzle with profile reed.

The most commonly used air jet weaving process is the multiple nozzle with profile read.

Water Jet Weaving

Water jet weaving machine has limitation, since only hydrophobic (water-insensitive) yarns can be woven8. But these machines have been successful in the filament area

as it is a low cost machine with low level of energy consumption, characterised with simple maintenance feature.

Multi-phase Weaving

Within the last decade, Sulzer textile has developed a new multi-phase weaving machine called M8300 multi linear shed. M8300 is a multiphase air-jet weaving machine in

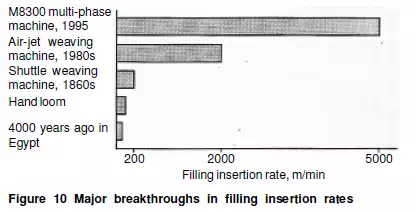

which four picks are inserted simultaneously. It has a filling insertion rate9 of over 5000 m/min. Figure 10 shows the filling insertion rate for different weaving processes10.

Single phase air-jet loom having 190 cm width typically weaves 23 m of fabric/h. However, M8300 multi-phase loom produces 69 m of fabric for the same width during the same time.

Triaxial Weaving

In this machine, two warp and one weft yarn systems are interwoven at an angle of 60o. The two warp yarn systems are taken from series of (six) rotating warp beam located

above the weaving machine. The result is interlacing of warp yarn at an angle of 60o. After leaving the warp beams, the warp ends are separated into two layers and brought

vertically down into interlacing zone. The weft is inserted by two rigid rapier with tip transfer at the centre of shed. Development of equipment to produce biaxially woven fabric is done by Barbar Colman Company, USA.

Circular Weaving

Circular weaving machines are not frequent in the textile industry due to the lack of flexibility in the fabric width and narrow range of options. Only sacks and tubes are woven on circular weaving machines. In this machine, weft revolves in

a circular path.