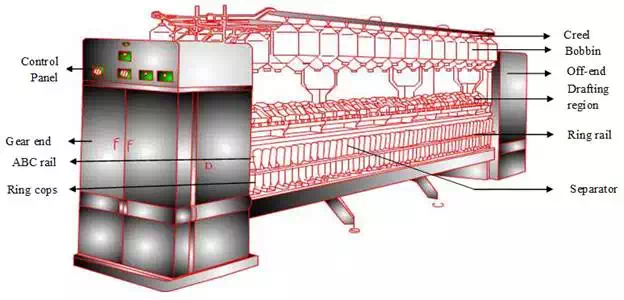

The ring spinning machine was invented in the year 1828 by the American Thorp. In 1830, another American, Jenk, contributed the traveller rotating on the ring. In more than 150 years that have passed since that time, the machine has experienced considerable modification in detail, but the basic concept has remained unchanged. Fig. 1 shows a typical ring frame.

The long central section of the machine, on which production is actually carried out, consists primarily of longitudinal members in the form of spindle rails and drafting rollers extending over the complete machine length.

These longitudinal members are secured to intermediate sections arranged at short intervals along the machine length. The sections also serve as supports for the creel .

The ring spinning machine has been the most widely used form of spinning and it will continue for some more time, because it has unique advantage over new spinning technologies:

· It is universally applicable, most of the textile fibres can be spun to required fineness.

· The yarn spun from this machine demonstrate excellent quality features like uniform structure and good strength.

· It is easy to operate as compared to other spinning machines

· The “know-how” for operation of the machine is well established.

· It is flexible as regard to quantities in terms of blend and lot sizes.

For these reasons, new spinning processes (with the exception of rotor spinning) have difficulty in gaining wide spread acceptance.

Disadvantages associated with ring spinning are:

More process stages. Roving stage exists as an extra process compared to the other systems.

Yarn breakages are more frequent as a result of ring traveller friction and yarn to air drag forces. Interruptions, broken ends and piecing up problems exist because of the yarn breakages.

o The high speed of the traveller damages the fibers.

o The capacity of the cops is limited.

o Energy cost is very high.

o Low production rate.

In long term, the ring frame can survive in longer term only if further success is achieved in automation of the ring spinning process. Also, spinning costs must be markedly reduced since this machine carries significant cost factor in spinning mill.

Comments are closed.