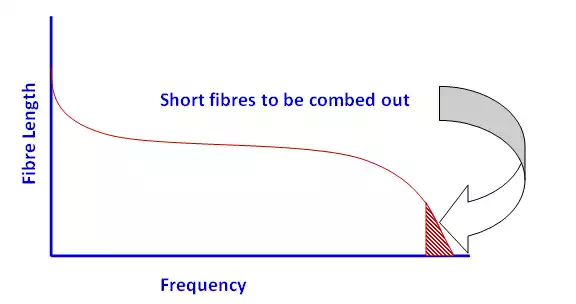

Combing process removes predetermined level of short fibres from the group of cotton fibres. It is well known that the cotton fibres have distribution of fibre lengths starting from long to very short fibres. Figure 1 shows a typical fibre length distribution diagram for cotton fibres.

The short fibres, shorter than 12 mm do not contribute to the strength of the yarn, but in turn they only increase the hairiness of the yarn and adversely affect the appearance and other good properties of the yarns and the fabrics made out of them. In the staple fibre yarn manufacturing process, only the trash particles, foreign matters and very short fibres are removed in the blow room and carding operations. In these processes, it is not possible to remove fibres which are shorter than a predetermined length, which can increase the average fibre length. In the combing operation, fibres shorter than length of fibres or certain fixed percentage of short fibres are removed. Since the shorter cotton fibres are generally coarser, removing the shorter fibres leaves behind fibres which are relatively finer. Hence, fabric made from combed cotton fibres has a very soft touch. Combing involves additional processing step and also certain amount of fibres are removed as waste. Hence, combed cotton is more expensive than conventional carded cotton.

The texture of combed cotton is softer since it is free from short fibres to stick out of the yarn surface and prickle, and all dirt and impurities have been removed from the yarn. Combed cotton is also stronger since shorter and weaker fibers have been removed through combing operation. The straightened fibers lie together in a more compact manner after combing, making combed cotton yarn less likely to fray and unravel. These aspects make the garments made with combed cotton yarns an excellent choice for garments intended to be worn by babies and the elderly, since it is gentle against the skin. The soft and strong combed cotton yarns are ideal for making bed linens and clothing which will be worn against the skin. If the yarn used in a cotton fabric product is combed cotton, it can usually be clearly identified by its luster.

On the other hand one has to keep in mind about the following shortcomings of having an additional combing section in the yarn manufacturing system.

Shortcomings of the Combing Process :

The combing section is an insertion of mostly three machines into the normal spinning process between card and draw frame. This needs more space with conditioned atmosphere which is becoming more and more expensive.

It serves as additional system to improve yarn quality if the carded yarn does not meet requirements. Certainly this process with three additional machines increases the cost of the yarn as it takes more energy and labour to run these machines.

The design of the comber itself is not very satisfactory since it works on intermittent processing basis which further increases the cost.

The entire mass of the nipper assembly has to be accelerated to the maximum speed and slowed down to zero about 7.5 times a second. Although it is a challenging task, the resulting intermittent processing also entails a loss in productivity

Operations in combing process :

· Elimination of a precisely predetermined quantity of short fibers.

Elimination of short fibers improves the staple length of the combed cotton. This also results in improving the finess of raw material. The short fibres removed in the combing process is called as “noils”. It is usually referred as a percentage of the total amount of material feed to the comber.

Noil percentage = (Weight of noil produced / Total weight of cotton fed) x 100

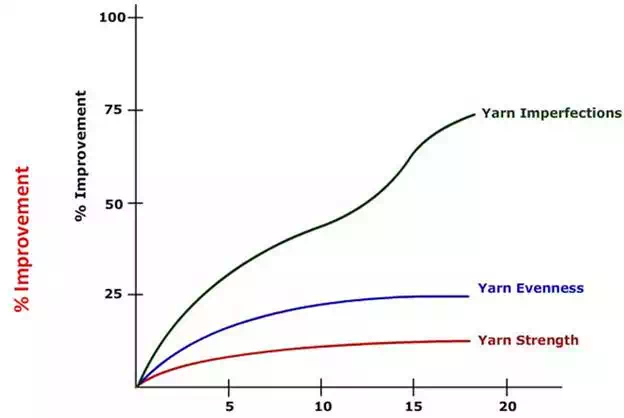

The amount of noils removed depends upon the industry and the needs ranging from 8 to 25%.Elimination of short fibers produces an improvement mainly in staple length , but it also affects the fineness of the raw material (Fig.2). Since noil is on average finer than the original raw material, the Micronaire value of combed sliver is slightly higher than that of the feedstock.

Elimination of the remaining impurities.

Although most of the larger and finer trash particles and foreign already removed in the blow room and carding operations, still some fine dust particles are found to present in the carded slivers. The combing operation involves fibre treatment almost to individual fibre state. There is fibre-to-fibre rubbing and action of combing needles on the surface of fibres. These actions enable the release of fine dust particles still adhering on to the fibre surface.

Elimination of neps in the fiber material.

Most of the neps which are already present in the bale cotton and those which are introduced in the blow room operations are supposed to be removed in the carding operation. Due to improper settings and conditions in the carding operation, some of the neps still remain in the carded sliver. In the combing process, these neps get either removed or straightened due to the action of the combing needles or inter fibre rubbing and sliding.

Formation of sliver having maximum possible fibre parallization.

It should also be noted that combing increases the parallelization of the fibers, but this is a side-effect which is not always an advantage. The high degree of parallelization might reduce inter-fiber adhesion in the sliver to such an extent that the fibers slide apart, e.g. while being pulled out of the can – i.e., sliver breaks or false drafts might be caused.