The Rotor:

The rotor is the main spinning element of the rotor-spinning m/c. Yarn quality ,character working performance of yarn productivity, & costs etc. all depend chiefly on the rotor. The most important parameters of the rotor that exert influence are

The rotor form

· The groove

· The rotor diameter

· Rotational speed along with

· The rotor bearing

· Co-efficient of friction b/w the fiber & the rotor wall.

· The air-flow conditions inside the rotor

· Liability to fouling

Rotors are replaceable element in the m/c.

· Tasks of the Rotor Spinning Machine:

· The basic tasks of the rotor spinning machine are

· Opening (& attenuating) almost to individual fibers (fiber separation).

· Cleaning.

· Homogenizing through back doubling.

· Combining i.e. forming a coherent linear strand from individual fibers.

· Ordering (the fibers in the strand must have an orientation as far as possible in the longitudinal direction).

· Improving evenness through back-doubling.

· Imparting strength by twisting

· Winding.

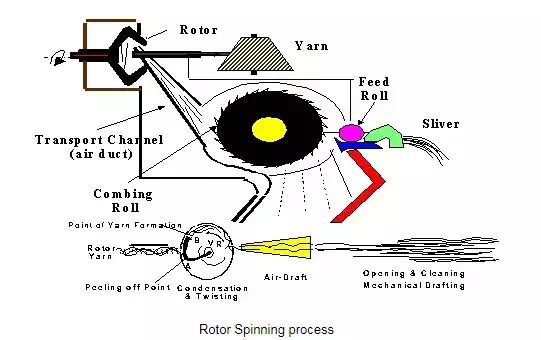

Principle of Rotor Spinning:

The general principle of rotor spinning is shown in Figure. The input fiber strand is a drawn sliver. A sliver may have more than 20,000 fibers in its cross-section. This means that a yarn of 100 fibers per cross-section will require a total draft of 200. This amount of draft is substantially higher than that of ring spinning. Drafting in rotor spinning is accomplished using a comber roll (mechanical draft) which opens the input sliver followed by an air stream (air draft). These two operations produce an amount of draft that is high enough to reduce the 20,000 fibers entering the comber roll down to few fibers (5-10 fibers). In order to produce a yarn of about 100 fibers per cross-section, the groups of few fibers emerging from the air duct are deposited on the internal wall of the rotor and a fiber ring is formed inside the rotor.

The total draft in rotor spinning is, therefore a combination of true draft from the feed roll to the rotor (in the order of thousands) and a condensation to accumulate the fiber groups into a fiber ring inside the rotor. The total draft ratio is the ratio between the delivery or the take-up speed and the feed roll speed. This should approximately amount to the ratio between the number of fibers in the sliver cross-section and the number of fibers in the yarn cross-section

Consolidation in rotor spinning is achieved by mechanical twisting. The torque generating the twist in the yarn is applied by the rotation of the rotor with respect to the point of the yarn contacting the rotor navel. The amount of twist (turns per inch) is determined by the ratio between the rotor speed (rpm) and the take up speed (inch/min). Every turn of the rotor produces a turn of twist, and a removal of a length of yarn of 1/tpi inches.

The winding operation in rotor spinning is completely separate from the drafting and the twisting operations. The only condition here is that the yarn is taken up at a constant rate. This separation between winding and twisting allows the formation of larger yarn packages than those in ring spinning.