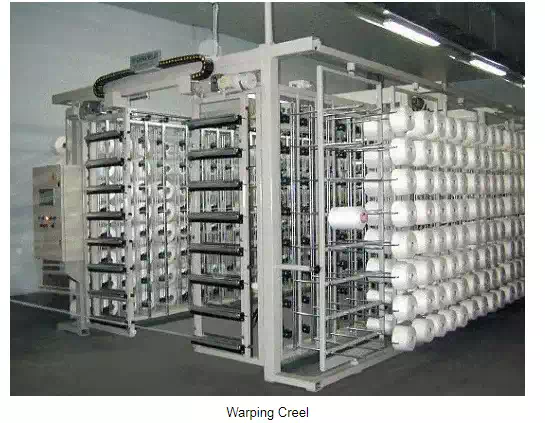

Creel:

Independently of the warping system, the threads are fed from bobbins placed on creels. The creels are simply metallic frames on which the feeding bobbins are fitted; they are equipped with yarn tensioning devices, which in modern machines are provided with automatic control and centralized tension variation. Moreover the creels are equipped with yarn breakage monitoring systems . The creel capacity is the parameter on which the number of warping sections or beams depends; it should be as high as the installation type and planning permit; the usual creel capacity amounts today to 800-1200 bobbins. Various solutions have been designed to reduce the time required to load the creel and thus increase the warping performance.

Types of Creel:

Mobile Creel:

this creel type is similar to the standard creel, but is formed by trolleys which can be taken individually out of the creel. The bobbins are creeled up on each trolley outside the creel. During the creeling up of a series of trolleys, the second series of trolleys is brought back to the outside of the creel to feed the warper. This reduces considerably the waiting time. The mobile creel comes in handy especially when there is insufficient room to permit the use of two standard creels.

Magazine Creel:

this kind of creel is used when several warps of similar type must be prepared in

sequence, that is when large lots of similar yarns need to be processed. Level with each tensioner, two bobbins are positioned: one operating and the other as reserve.

Swivel Frame Creel:

this type of creel was designed as a variation of the mobile creel to enable the creeling up of bobbins which, owing to their heavy weight (5 to 25 kg), cannot be pinned on trolleys. Each bobbin holder is double-sided: the threads are unwound from one side, while a new series of bobbins is creeled up on the other side.

V-shaped Creel:

In this creel type, the creel boards are assembled in form of endless chains. While warping is carried out from the outer sides using the already creeled up bobbins, the subsequent yarn lot can be creeled up on the empty spindles positioned inside the creel. This interior room serves at the same time as storage and bobbin exchange station. The yarn lot can be changed by simply pushing a button, which starts the electrically drive of the chains. The empty bobbins move towards the inside of the creel, the full bobbins towards the outside.