Textile wet processing get the challenges of reduce environment pollution to save the green world. This is so important to reduce usages of water chemical and dyes in wet processing. Wet processing is most of important department in textile which is plays a vital role to makes color and various textile process. Ultrasonic makes the wet processing easy and better than conventional system in a few selected methods. Let’s discuss the process of ultrasonic.

Meaning of ultrasonic (Ultrasound)

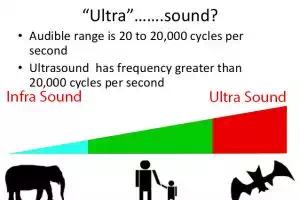

Ultrasonic made from two different words, ultra mean beyond and sonic mean sound. Ultrasonic defined the sound which limit is more than human limitations. Ultrasonic is a sound waves which frequencies are above the limitation of human audibility. More than hearing ability (>20 KHz) are called ultrasonic.

The human ear can respond to minute pressure variations in the air if they are in the audible frequency range, roughly 20 Hz – 20 kHz. It is capable of detecting pressure variations of less than one billionth of atmospheric pressure.

Sound Classification

· 1-20 Hz – Infrasound

· 20 Hz-20 KHz – Acoustic (low Base Notes)

· 20 KHz-2 MHz – Animals and chemistry, medical and destructive (Ultrasound).

· 2 MHz-200 MHz – Diagnostic and NDE

Production of ultrasonic.

Ultrasonic can be produced by following methods

· Piezo-electric generator

· Magneto-striction generator

Advantage of ultrasonic in textile wet processing.

· Increasing material swelling properties in water.

· Reducing glass transition temperature of the fiber or cloth.

· Increasing fiber and dye bath partition co-efficiency. Enhancing transport of the dye to the fiber surface by reducing the boundary layer thickness.

· Saving energy.

· Breaking of micelles and high molecular weight aggregation into uniform dispersion in the dye bath.

· Reduction the consumption of chemical and dyes.

· Reduction of processing time.

· Improvement of in quality.

· Easier process control.

· No hazard effect during process running.

· Reducing the pollution load on effluent water.

· Saving in energy.

· Low production cost and makes more profit.

Ultrasonic in textile industry

This is the most effective process in textile wet processing which is can be divided in to two main category.

§ Utilization in auxiliary process

§ Sizing process

§ Emulsion preparation

§ The modification of textile wet processing.

§ Desizing processing

§ Scouring and bleaching

§ Enzymatic treatment

§ Dyeing

§ Dispersion

§ Degassing

§ Diffusion

§ Finishing

§ Washing

§ Cleaning or washing action

§ Advantages

§ Deeper and quicker cleaning effect

§ Low energy expense

§ Reduced water expenses.

§ Reduced detergent and other accessories expense.

§ It does not damage the fiber.

Ultrasonic is a different way to increase wet processing procedure and let it be so effective. Though this is a process of sound weave but it is reduce the cost of goods and increase profit.