Introduction:

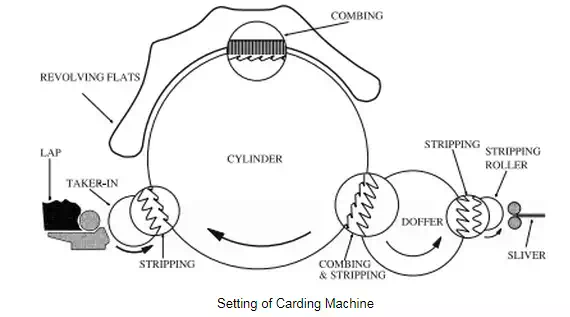

Carding is the most important process in spinning. It contributes a lot to the yarn quality. The following process parameters and specifications are to be selected properly to produce a good quality yarn with a lower manufacturing cost cylinder wire(wire angle, height, thickness and population) flat tops specification licker-in wire specification doffer wire specification feed weight draft between feed roller and doffer cylinder grinding doffer grinding flat tops grinding cylinder, flat tops, doffer wire life Licker-in wire life Cylinder speed flat speed Licker-in speed setting between cylinder and flat tops setting between licker-in and feed plate setting between lickerin and under casing elements like, mote knife, combing segment etc. setting between cylinder and doffer setting between cylinder and back stationary flats setting between cylinder and front stationary flats setting between cylinder and cylinder under casing.

Cylinder Wire and Cylinder Speed:

Cylinder wire selection is very important, it depends upon cylinder speed, the raw material to be processed and the production rate. The following characteristics of cylinder wire should be considered.

Wire angle

Tooth depth

Wire population

Rib thickness

Tooth profile

Tooth pitch

Tooth point

Overall wire height

Wire front angle depends on mainly cylinder speed and coefficient of friction of raw material. Higher the cylinder speed, lower the angle for a given fibre. The cylinder speed in turn depends upon the production rate. Higher production means more working space for the fibre is required. It is the wire that keeps the fibre under its influence during carding operation. Therefore the space within the wire should also be more for higher production. Higher cylinder speed also increases the space for the fibre. Therefore higher cylinder speed is required for higher production. In the case of high production carding machines, the cylinder surface is very much higher, therefore even with higher number of fibres fed to the cylinder, the cylinder is renewing the carding surface at a faster rate.

Higher the cylinder speed, higher the centrifugal force created by the cylinder, this tries to eject the fibre from the cylinder, along with the trash. It is the cylinder wire’s front angle which overcomes the effect of this force. Low front angle with too low cylinder speed and with high frictional force will result in bad quality, because the fibre transfers from cylinder to doffer will be less. Hence recycling of fibres will take place, which result in more neps and entanglements. The new profile with less free blade avoids loading of the cylinder with fibre and/or trash. This helps in keeping the fibres at the tip of the tooth. The movement of the fibres towards the tip of the tooth coupled with centrifugal action demands an acute front angle to hold the fibre in place during carding. Lack of stiffness associated with fine and/or long fibres necessitates more control during the carding process. This control is obtained by selecting the tooth pitch, which gives the correct ratio of the number of teeth to the fibre length. Tooth pitch reduction is therefore required for exceptionally short fibres and those lack stiffness. Number of points across the carding machine is decided by the rib width. It is selected based on the production rate and fibre dimensions. Finer the fibre, finer the rib width. The trend is to finer rib width for higher production.

The population of a wire is the product of the rib thickness and tooth pitch. The general rule is higher populations for higher production rates, but it depends upon the application. Sharp tooth points penetrate the fibre more easily and help to intensify the carding action. Cut-to-point wires are sharp and they have no land at all. The effective working depth of a cylinder wire tooth for cotton is approximately 0.2mm and for synthetic materials approx.0.4mm. Manmade fibres require more space in their cylinder wire than doe’s cotton. More tooth depth allows the fibre to recycled, resulting in damaged fibres and neps. If tooth depth is insufficient, there will be loss of fibre control. This will result in even greater nep generation. Looking into the above details, the following specifications can be used as a guideline.