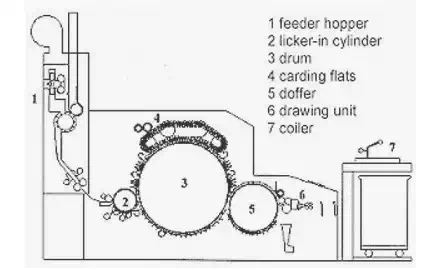

Carding is one of the most important operations in the spinning process as it directly determines the final features of the yarn, above all as far as the content of neps and husks are concerned. There are many objectives of the carding process and these can be summarized as:

Opening the tufts into individual Fibres.

Eliminating all the impurities contained in the Fibre that were not eliminated in the previous cleaning operations.

· Selecting the Fibres on the basis of length, removing the shortest ones.

· Removal of neps.

· Parallelizing and stretching of the Fibre.

· Transformation of the lap into a sliver, therefore into a regular mass of untwisted Fibre.

And in this action you can see two actions. They are;

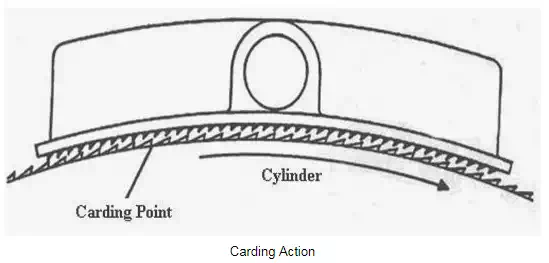

Carding Action

Stripping Action

1. Carding Action

When two close surfaces have opposite wire direction and their speed direction or relative motion is also opposite. Then the action between two surfaces is called carding action.

Functions:

It is occurred between flats and cylinder.

· Maximum individualization of fibers is achieved in this region.

· Naps short fibers dirt and dust are removed by this action.

· There always should be point against point action.

2. Stripping Action

When two close surfaces have same wire direction and their speed direction or relative motion is opposite then the action between two surfaces is called stripping action.

Functions:

It is occurred between licker in and cylinder.

· There are should be point against back action.

· Individualization of Fibre is also by this action.