Clay Products

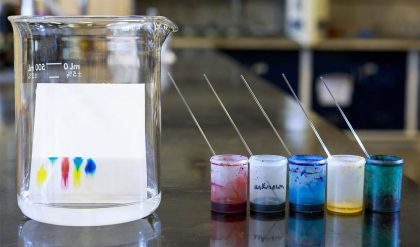

Many common ceramics such as bricks and tiles are based primarily on clay. These are pressed or extruded into shape while in a wet plastic state and then dried and fired.

Higher density clay products exhibit better mechanical properties but at the same time have worse insulating properties.

Increased vitrification leads to higher densities and is achieved through finer original particle size and increased firing temperature

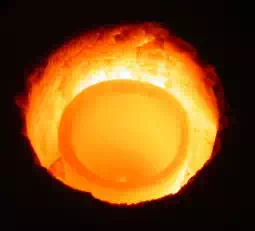

Refractories

Because of their high heat resistance, ceramic materials are used as refractories.

Refractory ceramics are insulating materials and are designed to withstand high stresses and temperatures and must also resist the effects of molten metals, abrasive particles and hot gases.

Ceramics made of pure oxides are quite often the best refractories, however, these are expensive and therefore mixtures of ceramic compounds are often used.

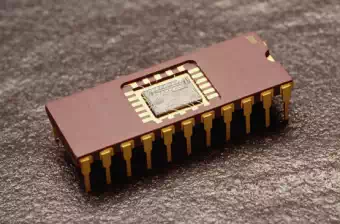

Electrical Ceramics

Ceramics can display a variety of useful electrical and magnetic properties.

Some ceramics are good conductors such as graphite while some have high resistivity such as SiC which is used in heating elements.

Unlike in metals, the conductivity of ceramics increases as temperature increases. This is because conduction is based on the movement of anions and cations. Mobility of the ions is only possible when there is enough thermal heating to supply sufficient energy.

Magnetic Ceramics

Magnetic ceramics are divided into two categories – traditional low conductivity magnets and superconducting magnets.

Low conductivity magnets are used in applications where the magnet is required to have some electrical insulating properties, such as in transformers.

Superconducting magnets are a special class of ceramics that are able to conduct electricity with no resistance and therefore no energy loss. This special property is limited, however, as it is only possible below a critical magnetic field and a critical temperature, TC, which is always very cold.

Abrasive Ceramics

Abrasive ceramics are used to grind or cut away other softer material. Primarily, when considering the design of a abrasive material it is hardness and wear resistance that are of the most importance. Toughness is also considered as a necessary requirement so that the abrasive material does not shatter during grinding.

Abrasives can be either natural or synthetic. Common examples include diamond, silicon carbide SiC, tungsten carbide WC, or normal silica sand.

Abrasives may generally be either bonded to grinding wheels, coated on paper, or exist as loose grains