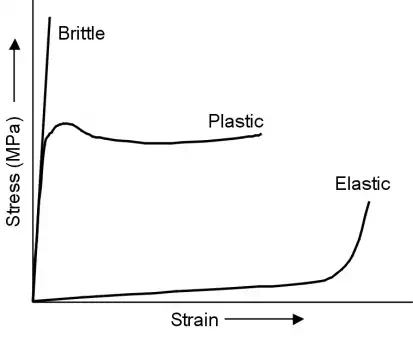

Three typically different stress-strain behaviours can be observed in polymeric materials.

A brittle polymer deforms elastically before fracture, a plastic polymer deforms elastically at first and then yields into a region of plastic deformation, and an elastic polymer shows totally elastic deformation at large strain levels.

Brittle or Ductile

Below their glass transition temperature thermoplastics deform principally by elastic deformation, i.e. they are brittle. Above Tg they deform principally by plastic deformation, i.e. they are ductile. Thus thermoplastics go through a brittle to ductile transition when heated through their Tg.

Temperature also has a significant effect on the strength of a thermoplastic. Generally, a thermoplastic loses strength as it is heated because the secondary bonding forces between the molecular chains become weaker. When it is heated through its Tg a significant drop in strength occurs as the secondary bonding forces are fully overcome.

Thermosetting plastics also lose strength when heated but do not become viscous like thermoplastics due to the network of strong covalent primary bonds that make up their atomic structure.

Heated thermosets will tend to degrade or char above their maximum use temperature. Generally, thermosets are more stable at higher temperatures than thermoplastics.

Brittle Polymers

Both thermosets and thermoplastics that are well below their Tg, usually 0.75Tg, exhibit brittle behaviour.

In the brittle state the polymer chains are locked into place through a strong interlocking network making plastic flow difficult. Like glasses and ceramics, polymers contain flaws which can cause them to fracture prematurely

Ductile Polymers

Thermoplastics above their Tg usually exhibit ductile behaviour. Under an applied stress these polymers plastically deform past their yield strength in a manner known as cold drawing.

Cold drawing involves viscous flow where the chains slide past one another. Initially, the chains may be highly tangled but the applied stress forces them to elongate and align in a single direction.

Once the chains are fully aligned a higher stress is required for fracture.