There are three basic types of printing – direct, discharge and resist

Direct Printing

The most common and direct approach to apply color pattern on the fabric is by directly printing on a white or dyed background using some coloring agent which is prepared in the form of a paste. The printing paste is prepared by dissolving a known quantity of dye in limited amount of water to which a thickening agent gums, glues, alginates, resins etc may be added to provide necessary viscosity to the paste. Pigment printing is done without thickeners and is used as such; the consistency is obtained by mixing resins, solvents and water in required proportion.

Discharge Printing

It is another approach of applying color to the fabric. The color is destroyed or removed from the designed areas of the piece dyed fabric. Sometimes the ground color is removed and printed with another color in its place. Usually, a white or light pattern is desirable to enhance the bright and dark ground color.

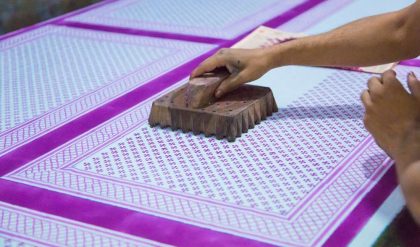

Resist Printing

In this method, a substance impermeable to dye or water is coated on the fabric in prescribed area which prevents the absorption and penetration of the dye. The resisting agent seals the air pores in the fabric, thus making it non-porous. The resisting agents used may be natural or of synthetic origin e.g., starch, wax, clay, resins, glue, gum, gelatin and synthetic or chemical agents.

Methods of Printing

Patterns produced in different colors and style often add value to enhance the aesthetic appeal, add variety, novelty, symbolism and is a means of expression. As often color gives meaning to the design, design in turn gives meaning to colors. There different methods of printing that are practiced.