Radio frequency identification device (RFID):

A micro-chip in a label used to transmit data when the label is exposed to radio waves. RFID is an Automatic Data Capture technology that uses radio-frequency waves to read a movable item to identify, categorize & track. RFID is fast, reliable, and does not require physical line of sight or contact between reader/scanner and the RFID tagged item.

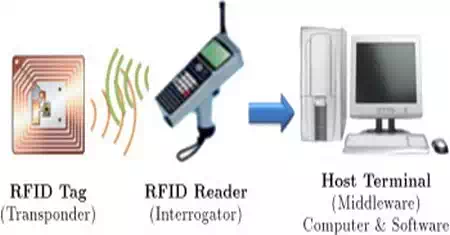

RFID systems consist of three basic components:

1. A tag (also called a transponder),

2. An interrogator (a reader or a read/write device) and

3. A controller (a host).

|

| Fig: Basic components of RFID |

Working process of RFID:

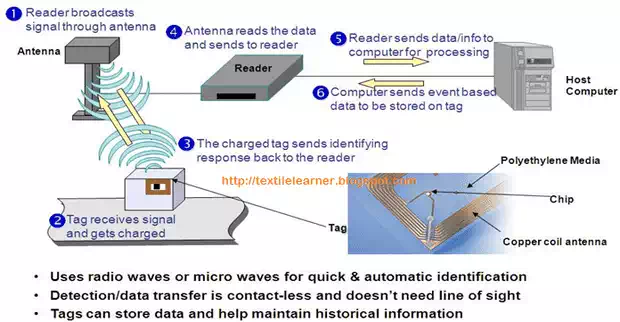

RFID systems consist of three basic components: a tag (also called a transponder), an interrogator (a reader or a read/write device) and a controller (a host). RFID tags consist of an integrated circuit (IC) attached to an antenna, ie, typically a small coil of wires covered with some protective packaging (like a plastic card) as determined by the application requirements. Data is stored in the IC and transmitted through the antenna to a reader. RFID tags are either “Passive” (no battery) or “Active” (self-powered by a battery). Tags also can be read-only. (ie, stored data can be read but not changed) or read/write (stored data can be altered or rewritten), or a combination, in which some data is permanently stored while other memory is left accessible for later encoding and updates.

|

| Fig: Working process of RFID |

RFID in textile and apparel industry:

Product tracking system:

1. In textile industry it is used to avoid product mix.

2. In carding, drawing and combing sliver can hank mix up.

3. In simplex bobbin mix up can be avoid by placing tag.

Tracking of labor movement:

1. RFID reader detects an RFID-tagged employee approaching a security door, the door could be designed to open automatically.

2. If store management could verify through an automated system that an employee was at the appropriate station at the start of the shift or end of a break that can be possible by the RFID system.

RFID in fabric lot storage:

RFID requires in fabric lots because after dyeing each fabric lots have different shades as a result there have possibility to mix up the fabric lots when its passed into the sewing section. So that it decrease the shade variation and product mix up.

Merchandise levelling across stores:

Some stores require customers to leave merchandise that they are carrying at a desk or provide evidence of purchase. However, if a store has RFID readers and RFID-tagged merchandise, shoppers could avoid this step. Instead, at checkout, the readers would charge customers only for items with tags that indicate that they were not already paid for.

Easy product accessibility in retail stores:

1. By using RFID, shop sellers can identify the exact location of any retail item at any time.

2. Customer requests can be handled quickly and easily by your customer service team through access to a centralized database.

RFID in supply chain errors:

RFID can be used to track the movement of the goods that go out of warehouses. In this case, as soon as a certain goods item goes astray on the way from the warehouse to the place of production, information about the same can immediately be obtained at the point of control. Wastage and theft can thus be minimized, and the possibility of errors in the supply chain can be brought down drastically. This, in turn, would lead to timely completion of the production process and savings in cost.

Conclusion:

By this topic we learn about the mechanism of RFID in different textile and garments section. It is mostly important technology used in textile and apparel industry that will increase the efficiency and productivity of this sector.