Materials:

Turmeric Powder:

The roots of turmeric are collected from the market. Then collected turmeric roots are washed with clean water to remove the dust and impurities. Cleaned turmeric was dried in open sunlight. Then, the root soft turmeric powder is stored in dry container. The powder of turmeric roots was used as coating material for the cotton fabric in our research.

Chitosan:

Chitosan polymer was supplied by Central Institute of Fisheries Technology, Cochin, India.

Cotton Fabric:

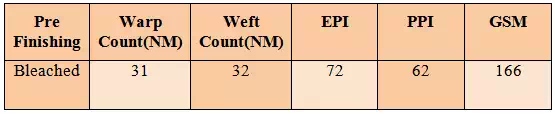

100%Woven cotton bleached (woven) fabric is used in this research with the following properties.

|

| Table3.1: Specifications of the fabric used for treatment |

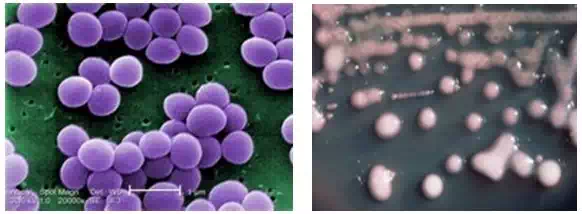

Microorganisms:

The microorganisms used for the study includes human pathogenic gram positive bacteria such as Staphylococcus aurous and gram negative bacteria such as Escherichia-coli.

|

| Figure 3.1 Staphylococcus Figure 3.2 Escherichia-coli |

Apparatus:

§ Beakers padding machine

§ PH Meter

§ Curing machine

§ Electric Balance

§ Washing machine

§ Scissor

§ Drying machine

§ Thermometer

Work method flow through the project:

TASK:1

Preparation of Cotton Fabric

↓

TASK:2

Preparation of Turmeric & Chitosan Solution

↓

TASK:3

Coating of cotton fabric with Different Proportions

↓

TASK:4

Testing of coated cotton fabric

↓

TASK:5

Result Analysis

↓

TASK:6

Thesis Preparation

Preparation of turmeric solution:

The turmeric solution is extracted from the fresh turmeric roots. The turmeric solution was prepared by the extracted turmeric powder & mixing it with water at neutral pH, at 95°c for 1 hours. The obtained turmeric solution had a yellowish color.

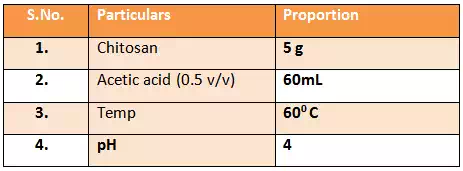

Preparation of chitosan solution:

The chitosan solution was prepared by dissolving 5 grams of chitosan flakes in 100 mL of 5% acetic acid (pH = 4).

|

| Table 3.2: Recipe for chitosan solution |

Then the solution was left standing overnight. After 12 hours, chitosan solution was stirred on a hot plate stirrer at 600 C for 30 min and filtered before use. The recipe for preparation of chitosan solution is given in Table 1.

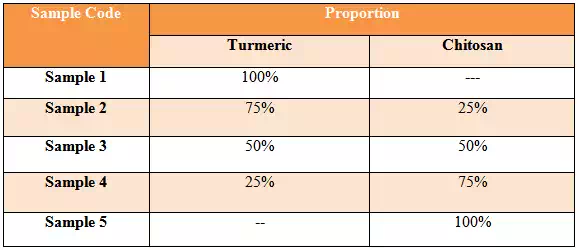

Coating of prepared solution on cotton fabric

The Solution was prepared by mixing with different ratio of turmeric solution and chitosan solution in a flask and stirring is done for uniform mixing.

The water bath is maintained at a uniform room temperature. Finally the Cotton fabric are taken and being coated with the prepared solution. Here we used M:L ration = 1:20.

|

| Table 3.3: Sample Coating proportion |

Application ways or working procure:

We prepare solution according to recipe calculation

↓

We Take sample of bleached cotton fabric

↓

Set the pickup of padded of padding machine at 70%.

↓

Set the temperature of curing machine for drying at 120°C for 1-2 minutes

↓

We Drop from the turmeric and chitosan solution in padding machine according the sample composition

↓

The fabric is dipped in a solution and on a padding machine

↓

Washing of the finishing fabric according the recommended time 4-6

↓

Drying and curing according to recommended temperature120°C for 1-2 minutes and 5 min at 150°C respectively.

Anti-microbial agent:

In this research turmeric is used as antimicrobial agent. These have been investigating as antimicrobial material against organism like algae, bacteria, yeasts and fungi in our experiments.

Universal Beer Agar (UBA):

Since it’s development at the Begia Brewing Company this has been a favorite medium for brewery microbiologists. This Medium may be described as a universal medium that will enable the growth of yeasts, worth spoiling bacteria, common Environmental bacteria (coli forms), and beer spoilers that require Oxygen. Satisfactory recovery is attained for worth and beer Microorganisms but this is not a differential medium; it only gives Total counts! Plates are generally incubated at 28◦C for about 48hisAerobic Incubation is needed for measuring overall sanitation for the detection of Yeasts and molds.

Quantitative Assessment by Percentage Reduction Test (AATCC 100-2004)

The quantitative determination of antimicrobial activity was based on the Absorption method from JIS L 1902:2008 and AATCC Test Method 100-2004 protocols.

The efficiency of the antimicrobial treatment was determined by comparing the reduction in bacterial concentration of the treated sample with that of control sample expressed as a percentage reduction in standard time.

% Reduction = [(A-B)/A] x 100 …..(1)

A where Aand B are the surviving cells (CFU/ml) for the flasks containing the control (uncoated cotton fabric) and test samples (coated cotton fabric), respectively, after 48 hrs of contact time.