Spinning is manufacturing process for creating polymer fibers. It is a specialized form of extrusion that uses a spinneret to form multiple continuous filaments. There are four types of spinning: wet, dry, melt, and gel spinning. First, the polymer being spun must be converted into a fluid state. If the polymer is a thermoplastic then it is just melted, if not then it may be dissolved in a solvent or chemically treated to form soluble or thermoplastic derivatives. The fluid polymer is then forced through the spinneret, where the polymer cools to a rubbery state, and then a solidified state.

Types of Spinning

There are different types of spinning. Such as:

1. Dry Spinning

2. Wet Spinning

3. Melt Spinning

4. Gel Spinning

Now they are descrived below:

1. Dry Spinning

Dry spinning is also used for fiber-forming substances in solution. However, instead of precipitating the polymer by dilution or chemical reaction, solidification is achieved by evaporating the solvent in a stream of air or inert gas. The filaments do not come in contact with a precipitating liquid, eliminating the need for drying and easing solvent recovery. This process may be used for the production of acetate, triacetate, acrylic, modacrylic, PBI, spandex, and vinyon.

2. Wet Spinning

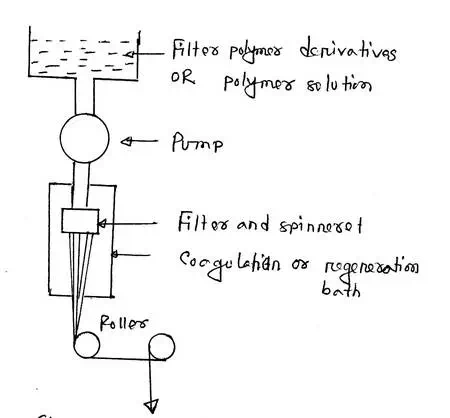

Wet spinning is the oldest process. It is used for fiber-forming substances that have been dissolved in a solvent. The spinnerets are submerged in a chemical bath and as the filaments emerge they precipitate from solution and solidify.

|

| Fig: Principle of wet spinning |

Because the solution is extruded directly into the precipitating liquid, this process for making fibers is called wet spinning. Acrylic, rayon, aramid, modacrylic and spandex can be produced by this process.

3. Melt Spinning

In melt spinning, the fiber-forming substance is melted for extrusion through the spinneret and then directly solidified by cooling. Nylon, olefin, polyester, saran and sulfar are produced in this manner. Melt spun fibers can be extruded from the spinneret in different cross-sectional shapes (round, trilobal, pentagonal, octagonal, and others). Trilobal-shaped fibers reflect more light and give an attractive sparkle to textiles. Pentagonal-shaped and hollow fibers, when used in carpet, show less soil and dirt. Octagonal-shaped fibers offer glitter-free effects. Hollow fibers trap air, creating insulation and provide loft characteristics equal to, or better than, down.

4. Gel Spinning

Gel spinning is a special process used to obtain high strength or other special fiber properties. The polymer is not in a true liquid state during extrusion. Not completely separated, as they would be in a true solution, the polymer chains are bound together at various points in liquid crystal form. This produces strong inter-chain forces in the resulting filaments that can significantly increase the tensile strength of the fibers. In addition, the liquid crystals are aligned along the fiber axis by the shear forces during extrusion. The filaments emerge with an unusually high degree of orientation relative to each other, further enhancing strength. The process can also be described as dry-wet spinning, since the filaments first pass through air and then are cooled further in a liquid bath. Some high-strength polyethylene and aramid fibers are produced by gel spinning.

Different Types of Yarn Spinning System

Spinning:

The present participle of the verb ‘to spin’ used verbally, adjectivally, or as a noun, meaning process or the processes used in the production of yarns or filaments.

The term may apply to:

(i) The drafting and, where appropriate, the insertion of twist in natural or staple man-made fibres to form a yarn;

(ii) The extrusion of filaments by spiders or silkworms; or

(iii) The production of filaments from glass, metals, fibre-forming polymers or ceramics.

|

In the spinning of man-made filaments, fibre-forming substances in the plastic or molten state, or in solution, are forced through the holes of a spinneret or die at a controlled rate. There are five general methods of spinning man-made filaments i.e. dispersion spinning, dry spinning, melt spinning, reaction spinning, and wet spinning, but combinations of these methods may be used.

In the bast and leaf-fiber industries, the terms ‘wet spinning’ and ‘dry spinning’ refer to the spinning of fibres into yarns in the wet state and in the dry state respectively.

Open-end Spinning;

Break Spinning:

A spinning system in which sliver feed stock is highly drafted, ideally to individual fibre state, and thus creates an open end or break in the fibre flow. The fibres are subsequently assembled on the end of a rotating yarn and twisted in. Various techniques are available for collecting and twisting the fibres into a yarn, the most noteworthy being rotor spinning and friction spinning.

Rotor Spinning:

A method of open-end spinning which uses a rotor (a high-speed centrifuge) to collect individual fibres into a yarn is known as Rotor spinning. The fibers on entering a rapidly rotating rotor are distributed around its circumference and temporarily held there by centrifugal force. The yarn is withdrawn from the rotor wall and, because of the rotation, twist is generated.

Friction Spinning:

A method of open-end spinning which uses the external surface of two rotating rollers to collect and twist individual fibres into a yarn is known as Friction spinning. At least one of the rollers is perforated so that air can be drawn through its surface to facilitate fibre collection. The twisting occurs near the nip of the rollers and, because of the relatively large difference between the yam and roller diameters, high yarn rotational speeds are achieved by the friction between the roller surface and the yarns.

Air-jet Spinning:

A system of staple-fibre spinning which utilizes air to apply the twisting couple to the yarn during its formation is known as Air-jet spinning. The air is blown through small holes arranged tangentially to the yarn surface and this causes the yarn to rotate. The majority of systems using this technique produce fasciated yarns, but by using two air jets operating in opposing twist directions it is possible to produce yarns with more controlled properties but of more complex structure.

Centrifugal Spinning:

A method of man-made fiber production in which the molten or dissolved polymer is thrown centrifugally in fibre form from the edge of a surface rotating at high speed. The term is also used to describe a method of yarn formation involving a rotating cylindrical container, in which, the yarn passes down a central guide tube and is then carried by centrifugal force to the inside of a rotating cylindrical container.

Dispersion Spinning:

A process in which the polymers that tend to an infusible, insoluble, and generally intractable character (e.g., polytetrafluoroethylene) are dispersed as fine particles in a carrier such as sodium alginate or sodium xanthate solutions is known as Dispersion spinning. These permit extrusion into fibers, after which the dispersed polymer is caused to coalesce by a heating process, the carrier being removed either by heating or by a dissolving process.

Draw-Spinning:

A process for spinning partially or highly oriented filaments in which the orientation is introduced prior to the first forwarding or collecting device.

Dry Spinning (man-made fiber production):

The spinning process involving conversion of a dissolved polymer into filaments by extrusion and evaporation of the solvent from the extrudate is known as Dry spinning.

Flash Spinning:

A modification of the accepted dry-spinning method in which a solution of a polymer is extruded at a temperature well above the boiling point of the solvent such that on emerging from the spinneret evaporation occurs so rapidly that the individual filaments are disrupted into a highly fibrillar form.

Flyer Spinning:

A spinning system in which yarn passes through a revolving flyer leg guide on to the package is known as Flyer spinning. The yarn is wound-on by making the flyer and spinning package rotate at slightly different speeds.

Melt Spinning (man-made fiber production):

The spinning process involving conversion of a molten polymer into filaments by extrusion and subsequent cooling of the extrude is known as Melt spinning.

Reaction Spinning (man-made-fiber production):

A process in which polymerization is achieved during the extrusion of reactants through a spinneret system.

Ring Spinning:

A spinning system in which twist is inserted in a yarn by using a revolving traveller is known as Ring spinning. The yarn is wound on since the rotational speed of the package is greater than that of the traveller.

Wet Spinning (man-made-fiber production):

The spinning process involving conversion of a dissolved polymer into filaments by extrusion into a coagulating liquid is known as Wet spinning. The extrusion may be directly into the coagulating liquid or through a small air-gap. In the latter case it may be known as dry-jet wet spinning or air-gap wet spinning.